The Effects of Static Electricity on Analytical Weighing

Introduction

Static electricity is a physical phenomenon that is a common occurrence in many areas of our daily lives. It can have tremendous significance in industry and all kinds of research and development laboratories. For example, the electrostatic charging of materials in industrial processes and during production sequences or materials analysis can have negative effects (e.g. dosing powders with a spatula or dosing heads risks spreading the substance so it cannot be brought into the vessel without spilling). Furthermore, electrostatic discharges can damage electronic equipment and components, while spark discharges can easily ignite flammable substances in the immediate vicinity, leading to serious accidents. Thus, millions of dollars are spent around the world on efforts to eliminate electrostatic charges and their associated negative effects.

Basics of Static Electricity

Static electricity results from friction between two objects (bodies). This friction process transfers electrons from objects with a lower work function (the 'donator') to objects with a higher work function (the 'acceptor'), which results in the production of ions (figures 1a and 1b). A body with excess electrons takes on a negative charge, while a body lacking electrons takes on a positive charge. However, this is only a temporary change in the charge because any excess electrons flow off of the body once it has a certain conductivity or is grounded.

Friction can occur within the sample itself or between the sample and container or tare vessel. For example, during convection in a drying oven, air friction creates a charge on glass containers. Furthermore, internal friction of powders and liquids when they are transferred between containers creates a charge on particles within that sample. In practice, it is impossible to avoid friction during the processing or transport of substances. Thus, electrostatic charging occurs nearly 100% of the time. Disruptive electrostatic forces can also occur in the area around the balance, due to the direct transfer of charge carriers by people moving around it.

Among the various options for eliminating static electricity during analytical weighing are simple, low-cost measures. However, due to current metrological and practical limitations, many of these measures are difficult and time-consuming to use and are not universally applicable. On the other hand, there are methods that are both powerful and space-saving, particularly when they are integrated directly into the balance.

Direct Impact on Weighing

All balance manufacturers are called upon to respond with appropriate technological solutions to the problems of weighing substances with electrostatic charges. Static electricity can have a negative effect on either the weighing process itself or on the results, thus requiring time-consuming material selection or material handling procedures to address these effects. In some cases, weighing a material may be close to impossible due to the build-up of electrostatic charges during handling. In addition, the electrostatic properties of some materials may vary as ambient humidity rises and falls, making the attempt to weigh it even more difficult. Often, electrostatic phenomena are worse when the relative humidity falls below 45%, which is often the case in winter in European latitudes or in air-conditioned rooms. Therefore, balance users will experience different conditions from one season to the next or from one day to the next, making it difficult to reproduce their results. Electrostatic charging of materials can occur under the following conditions:

- In solids where the surface resistance of the material (Rs) is >10 GΩ (according to IEC93)

- In liquids with a conductivity of <10 nS/m

- In conductive materials that are not grounded

During a weighing operation, the interaction of electrical charges that have built up on the material being weighed and the fixed parts of the balance that are not conductively connected to the weighing pan cause an electrostatic force to develop. Thus, an electric field builds between the material being weighed and the fixed parts of the balance. Some examples of fixed balance parts include the draft shield or housing and the balance base plate. The resulting electrostatic forces can cause load changes (displayed values) up to the order of a gram. In practice, a false absolute weight is not the only negative effect associated with static electricity. Severe drift of weight readouts and poor repeatability of results are also serious problems.

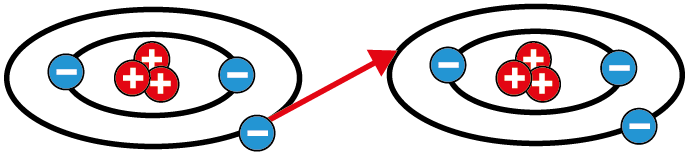

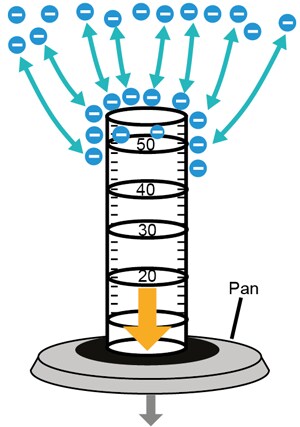

Built up charges flow off slowly via the weighing pan, such that the resulting forces are not constant over time, causing drift and poor repeatability. Depending on the polarity the charge carries, the interaction can be either repulsive or attractive, meaning the weight results can deviate both positively and negatively. A repulsive interaction occurs when both the charge on the sample and the ambient charge have the same polarity (both + or both –). The material being weighed thus seems heavier than it actually is (figure 2).

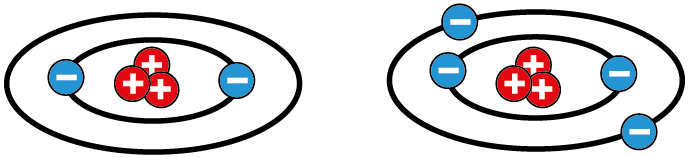

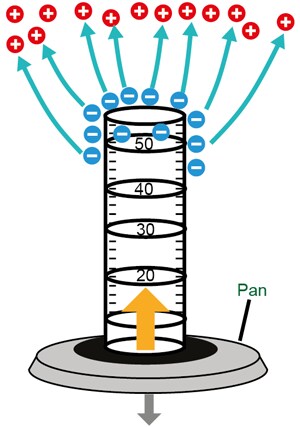

On the other hand, an attractive interaction occurs when the charge on the sample and the ambient charge have different polarities (one + and one –). An attractive interaction will, thus, make the material being weighed seem lighter than it actually is (see Fig. 3).

Neutralizing Electrostatic Charges

To eliminate the effects of static electricity on weighing, keep both the sample and the area around it free of any charges. One method that has yielded excellent results is to shield the weighing chamber and the weighing pan from electrostatic fields using a fully transparent conductive coating on all glass elements of the balance draft shield. All glass draft shields in the Cubis™ II series include this important feature. Another solution includes using ionizers and anti-static pens near the balance (figure 4). This solution works on the principle of surface neutralization via ion bombardment, which is very effective in those situations where charge buildup needs to be eliminated on vessels and samples in the external environment of the balance.

Below-balance weighing can be used for weighing bulky materials, such as plastic blocks. The sample is secured using a hanger beneath the weighing pan to take advantage of the proportional reduction in electrostatic force that occurs with the square of the distance between the charge carriers. Of course, this method of reduction of the influence of electrostatic charges can also be used while weighing on the weighing pan; any influence of electrostatic forces on weighing results can be reduced if the distance between the sample and the weighing pan is significantly smaller than the distance between the sample and the fixed parts of the balance, because the weighing pan provides an effective shield. However, if the opposite is true, electrostatic charges will still affect the weighing process. Sometimes it is sufficient to place an object between the sample and the weighing pan, reducing the forces to the point that they have no noticeable effect on the weighing result. For some applications, it is also enough to increase the shielding effect of the weighing pan. For this purpose, special pans with a greater diameter than standard pans are offered (figure 5).

Specific balances for weighing filters, which use a Faraday cage (a grounded metal shield) to solve the problem of electrostatic charges, are also available (figure 6). While weighing, the weighing pan and an electrically conductive cover attached to the pan shield the filters completely. Such filter weighing balances are often used to determine particulate matter in emission measurements in the automotive industry or environmental institutes.

Useful Equipment to Avoid the Influences of Electrostatic Charges

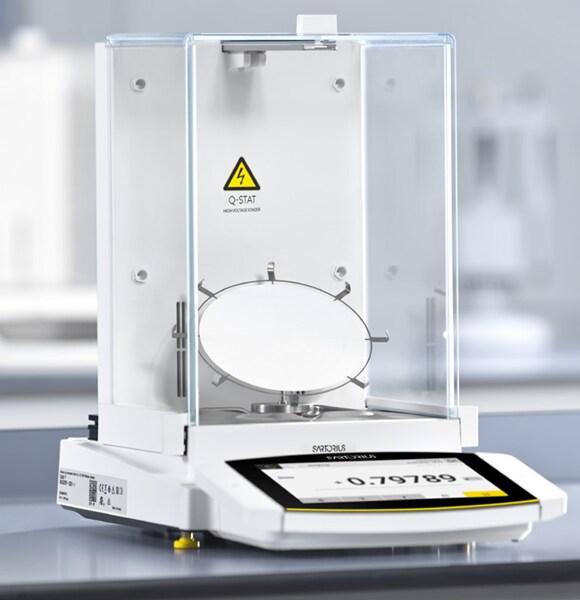

Generally, the time needed to neutralize electrostatic charges depends on the material, surface, and shape of the sample, as well as the relative humidity in the vicinity of the balance. Cubis™ II Balances offer the Q-Stat Ionizer, which is integrated into the Draft Shield I of the modular balance series (as four nozzles positioned in the rear wall) and eliminates electrostatic charges within a few seconds (figure 7).

The functional physical principle of these nozzles is corona discharge, a process by which a current flows from an electrode with a high voltage into the air. The electric field strength around a very thin needle is so high that the air molecules are ionized and create a region of plasma around the electrode. The generated ions pass charge to areas of lower potential and, after recombination with free charges, they form neutral gas molecules again. The use of four nozzles in the Cubis™ II Balance makes charge elimination very effective. By using opposite polarity nozzles, a kind of focusing effect in the area of the weighing pan occurs. This makes the neutralization of electrostatic charges from sample containers and substances (e.g. powders) without airflow disturbance very effective. Moreover, the fully transparent conductive layer on the glass draft shield panels of this model also provide additional protection from electrostatic fields in the immediate proximity of the balance. This too ensures stable and correct weighing results independent of electrostatic charge and allows the measurement of very small amounts of material (e.g. on filters), often with the use of accessory pans or filter holders (figure 8).